STUFFING AUTOMATION RANGE

SINGLE STUFFER

DOUBLE STUFFER

AUTOCUTTER

NET LOADER

STUFFING AUTOMATION IN DETAIL

SINGLE STUFFER

SS500SS500 Single Stuffer - Your First Step Into Automated Stuffing

About the SS500 Single Stuffer

The SS500 Single Stuffer from SCOTNET is the first step into automated stuffing. The SS500 is designed to offer an easy upgrade from manual stuffing, retaining the same netting tubes and loader.

Two operators can easily handle 600 - 800 joints per hour, with minimal fatigue.

- From Manual to Automatic - The change is simple, no new tubes, no new loader, just the SS500. The Scotnet manual range seamlessly integrates with the SS500.

- Reduce Fatigue - Let precision engineering handle the hard work streamline your operation, elevate performance, and focus your team where it matters most.

- Quick Diameter Change - Handles net sizes or tube diameters from 80mm to 200mm with quick, tool-free changeovers. The EH model is available for larger products up to 250mm in diameter.

- Casing Chambers - Finger style casing chambers can be used for stuffing into fibrous or plastic.

- Easy To Clean - Fully stainless steel design with quick-clean access built in, no tools or engineers required to prepare the machine for cleaning.

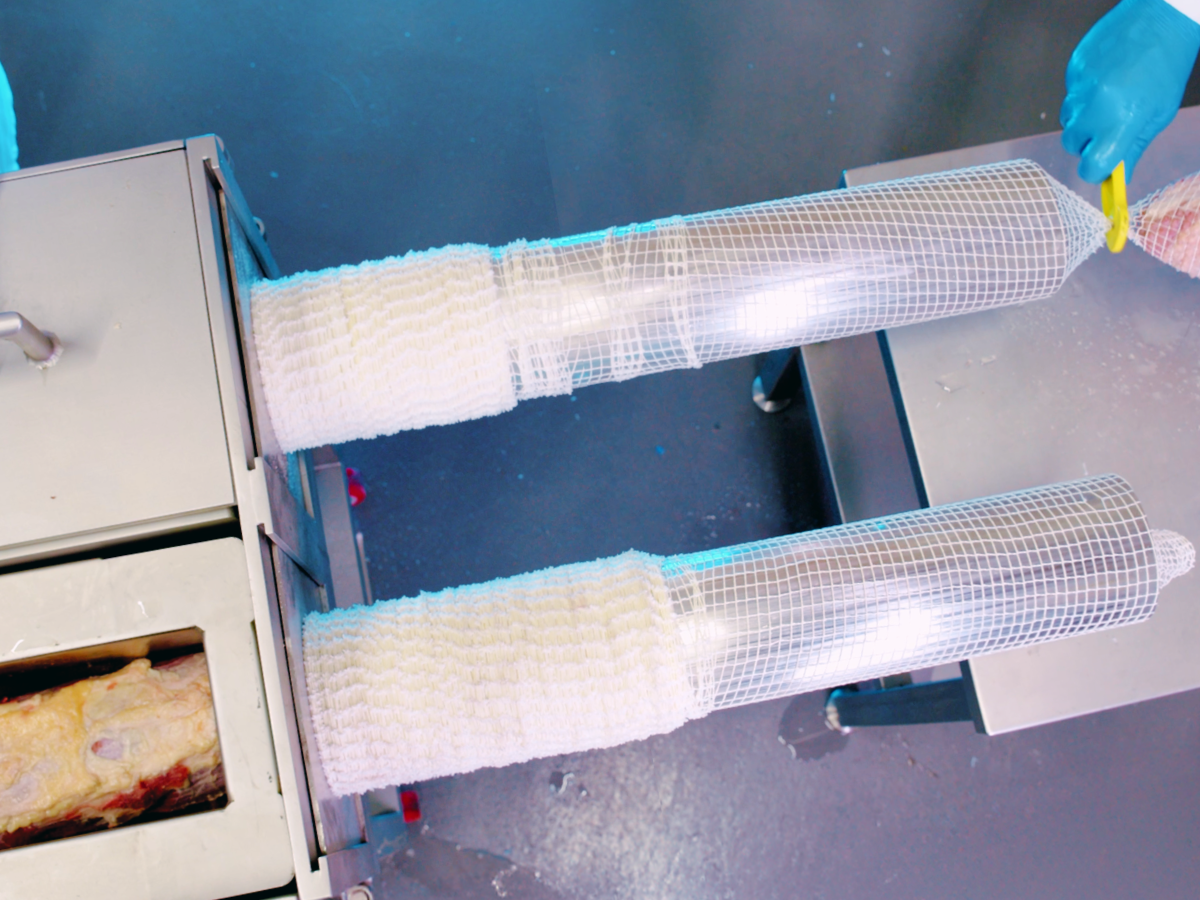

DOUBLE STUFFER

DS1200P7SDS1200P7s - The Original And Most Advanced Double Stuffer Ever

About the DS1200P7s Double Stuffer

The DS1200P7s is Scotnet's most advanced double stuffer to date - engineered to deliver high throughput, labour savings, and superior product consistency. With precision controls, remote monitoring, and intelligent automation, it outperforms both manual and single-stuffer setups with ease.

Two operators can easily handle 1200 joints per hour, with minimal fatigue.

- Reduce Downtime - Reduce downtime and achieve a consistent output of 1200 units per hour, with two operators. One operator loads the joint into the chamber, while the second cuts the netted joint from the opposite side. Downtime is eliminated as each operator is always working.

- Easy Operation - Operating the machine is simple, slide the lid to start the cycle, no buttons to press. The intuitive HMI touchscreen interface clearly shows if guards are not in place, and puts key functions, efficiency reporting, and diagnostics at your fingertips.

- Easy To Clean - Fully stainless steel design with quick-clean access built in, no tools or engineers required to prepare the machine for cleaning.

- Remote Monitoring - Reduce your engineering cost and line downtime by resolving issues remotely, whilst also tracking peak performance, with the secure cloud-based monitoring system.

AUTOCUTTER

DS1200P7AC3DS1200P7 AC3 - The Only Fully Automated Netting System Operated by One Person

About the DS1200AC3

The DS1200AC3 is SCOTNET's most efficient netting solution, combining high-speed output with fully automated functionality. Built for single-operator use, it transforms labour-heavy lines into streamlined, high-throughput operations. Reduce operators, improve consistency, and simplify your production process with the industry's only machine of its kind.

- Save Labour - Reduce Costs - Net over 1000 joints per hour with a single operator.

- Save Netting - Reduce Costs - Advanced sensors and precision controls ensure every cut is made close to the meat, leaving short, clean tails for a neater finish, less waste, and improved product presentation.

- Simple to Operate - Slide the lid to start the cycle, no buttons to press. Load the opposite side for continuous production.

- Reduce Downtime - Increase Output - Load more net per tube to minimise changes and reduce downtime on the line.

460mm Tubes, 20m per tube = 50 changes per 1,000m

700mm Tubes, 50m per tube (100m total on the stuffer) = 10 changes per 1,000m

Result: 40 fewer changes per 1,000m, saving time, labour, and increasing output. - Eliminate Springback - Springback occurs if the netting isn't applied squarely, causing blade cuts to damage multiple rubber strands when portioning. The DS1200AC3's unique centralising roller system ensures an even, square netting application, eliminating springback

- Eliminate Springout - Springout occurs from lengthwise compression during stuffing when the joint is pushed into the netting, causing the meat to spring out of the ends when portioned. Our bespoke roller system pulls the meat, elongating it, enhancing shelf appearance.

- Cleaning Simplified - Reduce your engineering cost and hygiene downtime due to the DS1200AC3's easy access and tool-free belt removal, chamber removal and tube removal. No engineers required.

- Advanced HMI - Operating the machine is simple and secure. The intuitive touchscreen interface puts key functions, efficiency reporting, and diagnostics at your fingertips, helping maintain control and optimise every cycle.

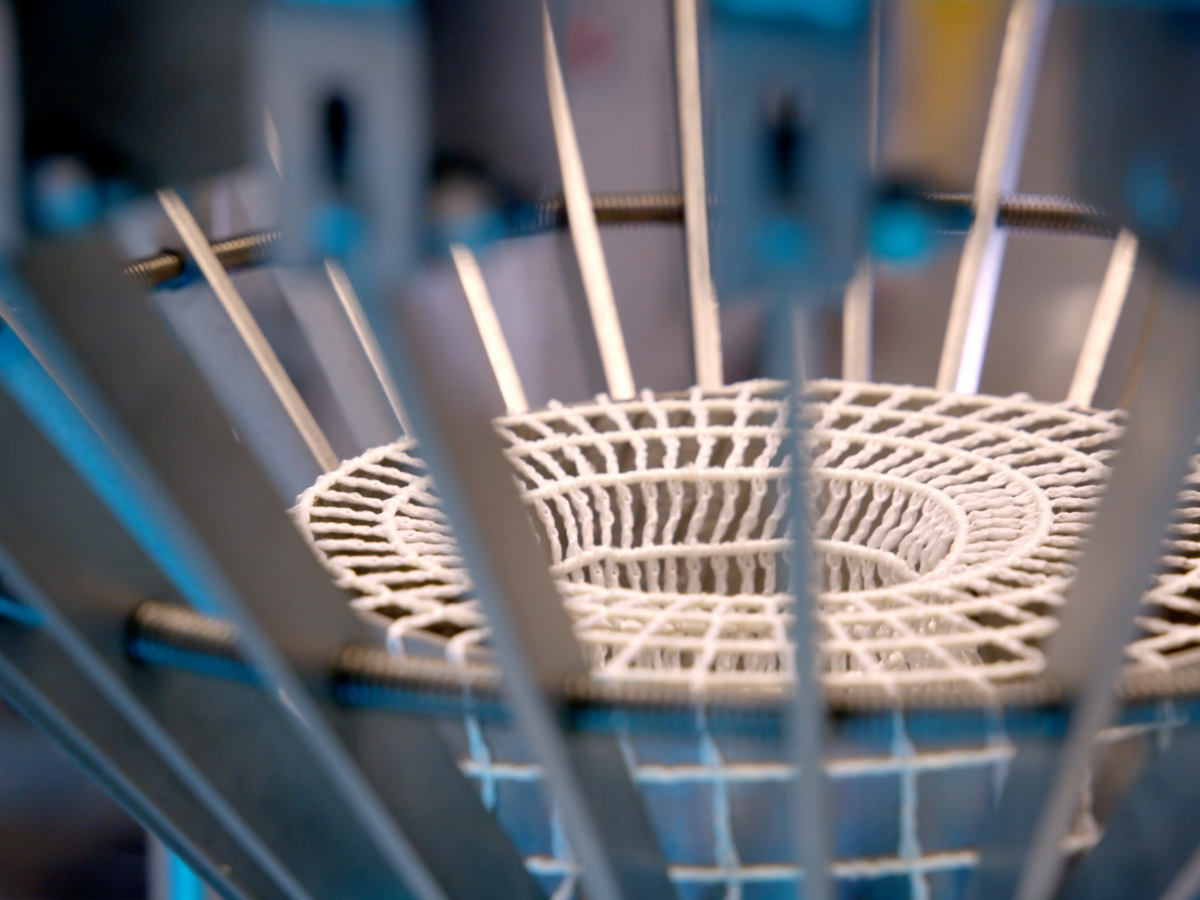

NET LOADER

NL6430STEffortless Loading For All Nets and Casings

Net Loading Simplified- Netting Rolls - The Scotnet and Casings Auto Loader accommodates standard netting rolls, offering fast, reliable application for high-throughput production. Quick-load functionality keeps changeovers minimal and operations running smoothly.

- Multi-Diameter Head - The multi-diameter head adapts to a wide range of tube sizes without adjustment. Perfect for agile, multi-SKU production lines.

- Super Bobbins - Compatible with super bobbins for extended run times and reduced handling. This format minimises downtime and maximises output between reloads.

- Quick Change Head - The quick-change head system enables engineers to change the head in minutes. Reducing maintenance and downtime to a minimum.